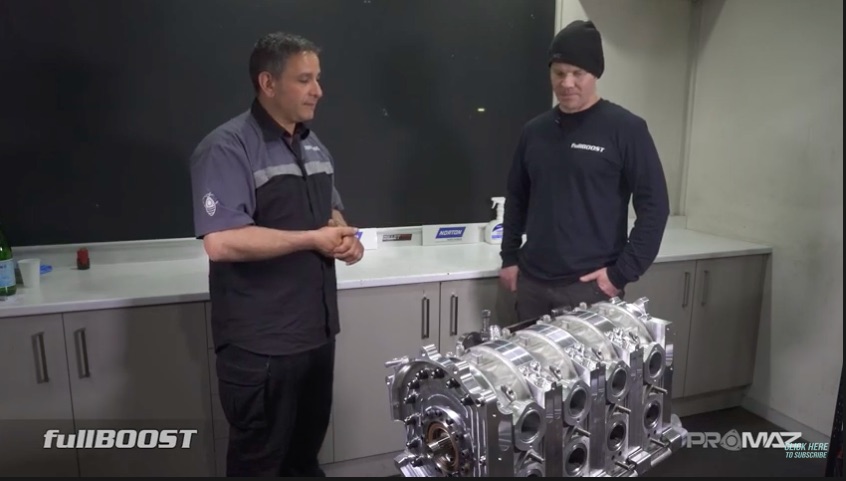

It’s time for Scott to get his 1965 Impala back on the road after years of neglect. But to do that means a new engine, new trans?, more power and even more fun. This is the 400 cubic inch Blueprint Engines Power Adder Small Block, which is the same engine we’ve made over 1,200 horsepower with after adding a Procharger and some other goodies. This engine is fully capable of supporting 1,000 horsepower and we know the short block is up the task of more than that for sure. In this video Scott goes through the specs on the engine, the process of building it and testing it, and what he plans to do with it in his Impala.

Here is all the information from Rebeldryver himself.

I am putting together my small block 400 from BluePrint Engines. This is their part number BP4003CT1. This is their power adder ready 400. Just add your own boost or nitrous to it and make big power from a small block Chevy. I am planning on installing twin turbos in the future. See it on their website: https://blueprintengines.com/products... This engine is destined for my 1965 Impala SS. In this video I am installing an Edelbrock 2925 Super Victor intake, Holley 0-4781S 850 double pumper, and a MSD 8360 ready to run distributor.

[embedded content]