I grew up in auto shops and at race tracks where tires were always balanced after being installed on a set of wheels. At my Grandpa’s or my Uncle’s shops it was super common place and I learned at my Grandpa’s on an old fashioned Bubble Balancer. Later on I would learn to use a Hunter rotational balancer at my Uncle’s shop, and would mount and balance wheels all the time. But the bubble balancer never went away, because every single Firestone, Goodyear, or Mickey Thompson slick that my dad ever had installed at the track was balanced with a bubble balancer. And if you go to the track today, Goodyear, MT, and Hoosier all have bubble balancers in their trailers and use them for slicks. Some of them do have newer digital rotational balancers as well, but these can only be used for smaller tires. In the drag radial world there are even folks who claim no balancing is needed. I don’t happen to subscribe to that philosophy myself, as I want a smooth drive on the road and no shaking when going fast on the track.

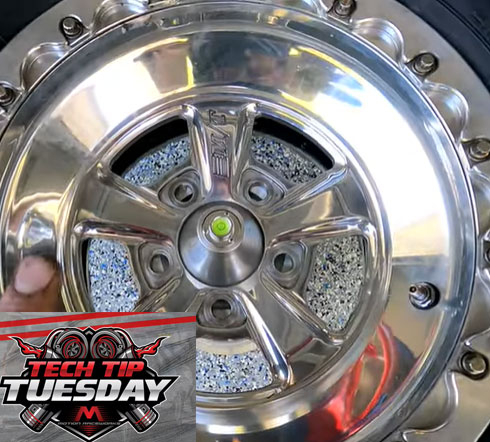

In this Tech Tip Tuesday, Doug from Motion Raceworks shows you how he balances his drag radials for his VERY low 7 second Nova and what he uses to do it. He also has some tips on weights for racing. Watch and learn and go buy a balancer.

[embedded content]